We specialize in SAE/BSP/METRIC hydraulic adapters and fittings.

The Ultimate Guide To Water Pipe Plugs: Everything You Need To Know

Welcome to our comprehensive guide on water pipe plugs – a one-stop resource that will leave you well-equipped with all the knowledge you need. Whether you're a plumbing enthusiast, a homeowner in need of quick fixes, or simply curious about the versatile applications of water pipe plugs, this article covers everything you need to know. From understanding their functionality and types, to exploring their uses in various scenarios, we've got you covered. Join us as we delve into the fascinating world of water pipe plugs, where you'll discover a wealth of information that will benefit you both professionally and personally.

What are Water Pipe Plugs and Their Importance?

Water Pipe Plugs are essential components in plumbing systems that help seal off water pipes, preventing leaks and damage. With their importance in maintaining the integrity of water pipelines, it is crucial to have a comprehensive understanding of what water pipe plugs are and how they function. In this article, we will provide an ultimate guide to water pipe plugs, covering everything you need to know.

What are Water Pipe Plugs?

Water pipe plugs, also known as pipe stoppers or sewer plugs, are mechanical devices used to seal off water pipes temporarily or permanently. These plugs are designed to fit inside the pipe, creating a tight seal that prevents water or other materials from flowing through.

Water pipe plugs can be made of various materials, including rubber, plastic, or steel, depending on the specific application and pipe material. They come in different shapes and sizes to accommodate different pipe diameters and plug requirements.

Importance of Water Pipe Plugs:

1. Leak Prevention: One of the primary purposes of water pipe plugs is to prevent leaks. Leaks can cause significant water wastage, leading to increased water bills and potential damage to the infrastructure. By sealing off the pipes effectively, water pipe plugs ensure that water remains contained within the intended system.

2. Maintenance and Repair: Water pipe plugs are invaluable during maintenance and repair work on water pipelines. When a section of the pipe needs to be isolated, a water pipe plug can be inserted to block the flow of water and allow the necessary repairs or maintenance to take place. Without these plugs, it would be extremely challenging to work on specific sections without shutting off the entire system.

3. Pressure Testing: Water pipe plugs are also used for pressure testing newly installed or repaired pipes. By sealing off the pipe and introducing pressure, any potential leaks or weaknesses can be identified before the pipes are put into full operation. This testing helps ensure that the system is fully functional and meets the desired standards.

4. Contamination Prevention: Water pipe plugs play a vital role in preventing contamination of water sources. For example, during repairs or maintenance work on sewage systems, water pipe plugs are used to isolate specific sections and prevent sewage from flowing into the water supply. This function is crucial in safeguarding public health and maintaining water quality.

Types of Water Pipe Plugs:

1. Inflatable Plugs: These plugs feature a flexible bladder that can be inflated once inserted into the pipe. Inflatable plugs are highly versatile as they can be adjusted to fit pipes of different diameters. They are commonly used in sewage systems, stormwater drains, and other applications requiring a tight seal.

2. Mechanical Plugs: Mechanical plugs are typically made of rubber or steel and rely on manual adjustment to create a seal. These plugs are commonly used in smaller pipes and can be useful in both residential and industrial settings.

3. Test Plugs: As the name suggests, test plugs are specifically designed for pressure testing purposes. They provide a temporary seal that can withstand high-pressure conditions during testing. Test plugs are commonly used in new construction projects or when assessing the integrity of existing pipes.

In conclusion, water pipe plugs are indispensable components in plumbing systems, serving multiple purposes such as leak prevention, maintenance and repair facilitation, pressure testing, and contamination prevention. Understanding the different types of water pipe plugs and their importance will enable individuals and professionals to make informed decisions when it comes to selecting and utilizing these crucial devices. By prioritizing the correct installation and usage of water pipe plugs, you can ensure the longevity and efficiency of your plumbing system.

Types of Water Pipe Plugs: A Comprehensive Overview

When it comes to water pipe systems, a crucial component that plays a significant role in maintaining the integrity and functionality of the system is the water pipe plug. Water pipe plugs are used to seal off pipes and prevent water from flowing through specific sections. In this comprehensive overview, we will delve into the various types of water pipe plugs, their uses, and how they are crucial in ensuring the efficiency of water pipe systems.

1. Inflatable Plugs:

Inflatable plugs are a popular choice when it comes to temporarily stopping the flow of water in pipes. These plugs are made of durable materials such as rubber or silicone and can be easily inflated using an air compressor. Inflatable plugs can adapt to different pipe sizes and provide a secure seal, making them ideal for construction projects, repairs, or maintenance work.

2. Mechanical Plugs:

Mechanical plugs, also known as expansion plugs, are another type commonly used in water pipe systems. These plugs feature a central nut or bolt that, when tightened, expands a rubber gasket. This expansion creates a tight seal within the pipe, effectively stopping the flow of water. Mechanical plugs are often found in residential plumbing systems, where they are used to close off pipes during repairs or when installing fixtures.

3. Freeze Plugs:

Freeze plugs, also known as frost plugs or expansion plugs, are primarily used in colder climates to prevent pipes from bursting due to freezing temperatures. These plugs are made of materials with low melting points, such as tin or aluminum, which allows them to pop out and release pressure if the water inside the pipe freezes and expands. Freeze plugs are an essential safety feature in water pipe systems, protecting against potential damage caused by freezing conditions.

4. Test Plugs:

Test plugs, also referred to as pressure testing plugs or pipe stoppers, serve the purpose of testing newly installed or repaired water pipe systems. These plugs are designed to withstand high levels of pressure without leaking. Test plugs often feature a threaded design, allowing them to be easily screwed into the pipe. They are commonly used by plumbers and contractors to ensure the integrity and functionality of water pipe systems before they are put into service.

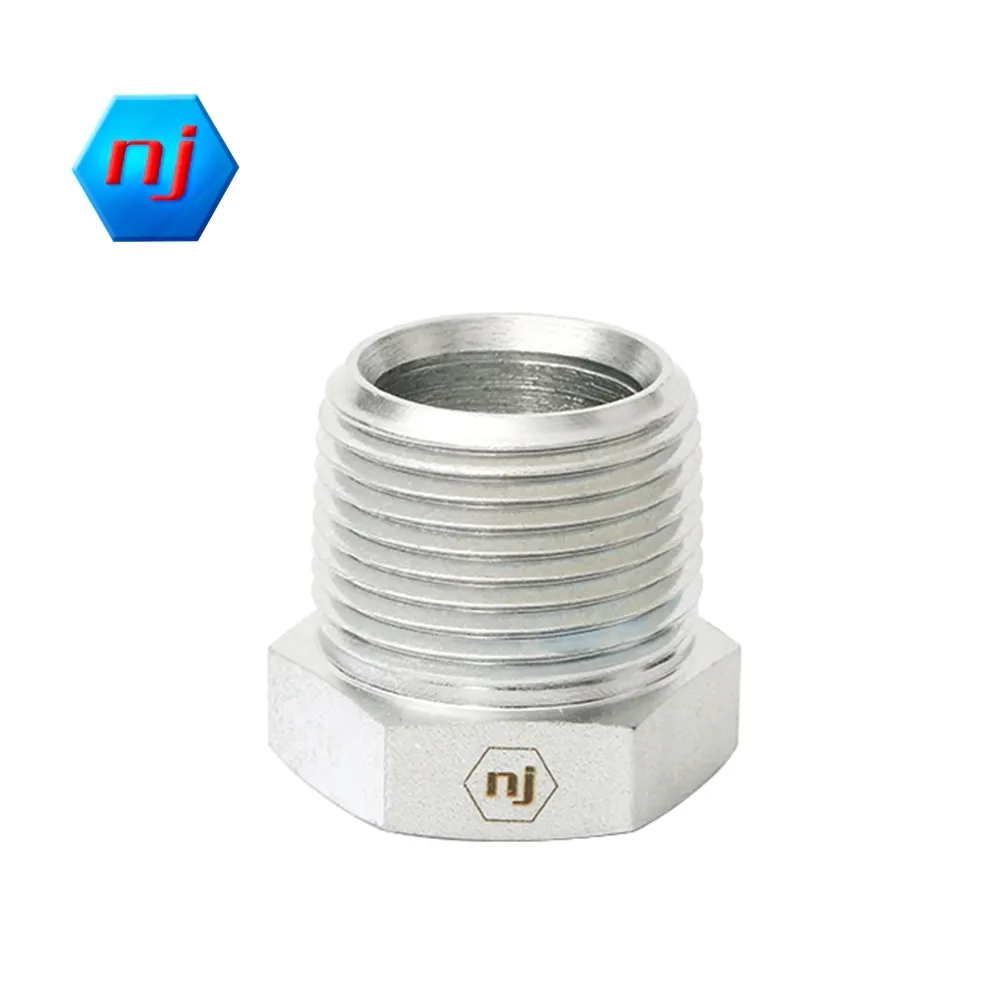

5. Threaded Plugs:

Threaded plugs are a versatile type of water pipe plug that can be used in various applications. These plugs have threads on the outside, allowing them to be screwed securely into the pipe opening. They provide a reliable seal and are commonly found in industrial settings or in plumbing systems where water pressure is a concern. Threaded plugs come in different materials, such as brass, steel, or plastic, to suit specific requirements.

In conclusion, water pipe plugs are crucial components in maintaining the efficiency and integrity of water pipe systems. Whether it be inflatable plugs, mechanical plugs, freeze plugs, test plugs, or threaded plugs, each type plays a vital role in sealing off pipes for repairs, maintenance, pressure testing, or protection against freezing temperatures. By understanding the different types of water pipe plugs available, users can make informed decisions when it comes to selecting the most suitable plug for their specific application. Trust NJ, your reliable source for high-quality water pipe plugs that meet industry standards and provide efficient and secure sealing solutions for water pipe systems.

Factors to Consider When Choosing Water Pipe Plugs

Water pipe plugs play a crucial role in maintaining the integrity and functionality of plumbing systems. These small yet essential components are used to seal off water pipes, preventing leaks and ensuring efficient water flow. Choosing the right water pipe plugs is vital to maintaining the overall efficiency and longevity of your plumbing system. In this comprehensive guide, we will delve into the various factors you should consider when selecting water pipe plugs.

1. Material and Durability:

One of the foremost factors to consider when choosing water pipe plugs is the material used in their construction. Different materials offer varying levels of durability, resistance to corrosion, and overall longevity. Common materials used to manufacture water pipe plugs include rubber, plastic, brass, and stainless steel. Each material has its own advantages and drawbacks, so it is important to select a material that aligns with your specific needs and budget.

2. Size and Compatibility:

Water pipe plugs come in a range of sizes to accommodate different pipe dimensions. It is crucial to measure the pipe diameter accurately to ensure the plug fits snugly. Undersized or oversized plugs can lead to leakages or may damage the pipes. Additionally, consider compatibility with different types of pipes, such as PVC, copper, or galvanized steel. Choosing plugs that are specifically designed for your pipe type will enhance their effectiveness and ease of installation.

3. Pressure and Temperature Ratings:

Water pipe plugs should be able to withstand the pressure and temperature conditions of your plumbing system. Ensure that the plugs you select have the appropriate pressure and temperature ratings to handle the specific demands of your application. High-pressure systems or those exposed to extreme temperatures may require plugs with higher ratings to avoid failures or rupture.

4. Leak-Proof Sealing:

The primary function of water pipe plugs is to seal off the pipes and prevent leaks. Look for plugs that provide a reliable and leak-proof seal. Rubber or silicone plugs, for instance, offer excellent sealing properties and can conform to uneven surfaces. Additionally, consider plugs with built-in gaskets or threading mechanisms for enhanced sealing capabilities.

5. Ease of Installation:

Simplicity and ease of installation are key factors to consider when choosing water pipe plugs. Look for plugs that are user-friendly and do not require specialized tools or skills to install. Quick and hassle-free installation ensures minimal disruptions to your plumbing system and saves valuable time.

6. Cost and Availability:

Consider your budget when selecting water pipe plugs, as their prices may vary depending on the material and brand. Compare prices from different suppliers or manufacturers to ensure you are getting the best value for your money. Additionally, check the availability of the plugs, especially if you require replacements in the future, to avoid any inconveniences.

When it comes to choosing water pipe plugs, there are several factors to consider to ensure the overall efficiency and longevity of your plumbing system. From material selection to size compatibility, pressure and temperature ratings, leak-proof sealing, ease of installation, and cost, each factor plays a crucial role in determining the effectiveness of the plugs. By carefully considering these factors and selecting high-quality water pipe plugs, such as those offered by NJ, you can ensure smooth water flow, prevent leaks, and enjoy a reliable plumbing system for years to come.

How to Properly Install and Maintain Water Pipe Plugs

Water pipe plugs are a crucial component for ensuring the proper installation and maintenance of water pipes. Whether you are a homeowner or a professional plumber, understanding how to properly install and maintain water pipe plugs is essential for the efficient and effective functioning of your plumbing system. In this comprehensive guide, we will delve into the details of water pipe plugs, exploring their importance, types, installation process, and maintenance tips.

Importance of Water Pipe Plugs

Water pipe plugs are essential for various reasons. They provide a seal and prevent the leakage of water from pipes, allowing for efficient water flow and preventing wastage. Additionally, they help in maintaining optimal water pressure within the pipes, ensuring the smooth functioning of the entire plumbing system. Without properly installed water pipe plugs, your plumbing system may experience leaks, reduced water pressure, and even significant damage over time.

Types of Water Pipe Plugs

There are several types of water pipe plugs available in the market, each designed for specific purposes. It is crucial to choose the right type of water pipe plug based on the pipe material, size, and application. Some common types of water pipe plugs include inflatable plugs, mechanical plugs, freeze plugs, and test plugs. Inflatable plugs are made of flexible materials and can expand to seal different pipe sizes. Mechanical plugs use mechanical force to create a tight seal, while freeze plugs are designed to temporarily seal or block off pipes during maintenance or repairs. Test plugs are primarily used for pressure testing purposes.

Proper Installation of Water Pipe Plugs

Installation of water pipe plugs requires careful attention to detail to ensure a secure seal. Firstly, you should make sure to choose the correct size and type of plug for your specific application. Clean the pipe thoroughly to remove any debris or contaminants that may affect the seal. Apply an appropriate lubricant to facilitate easy insertion of the plug into the pipe. Press the plug firmly into the opening until it is snugly fitted. Some plugs may require additional tightening using a wrench or other tools. Finally, check for any signs of leakage to ensure a proper installation.

Maintenance Tips for Water Pipe Plugs

Regular maintenance is essential to ensure the longevity and efficiency of water pipe plugs. Inspect the plugs periodically for any signs of wear, damage, or leakage. Replace any worn-out or damaged plugs immediately to prevent any potential issues or further damage. Additionally, clean the plugs regularly and remove any debris or sediment that may accumulate over time. This will help maintain the optimal functioning of the plugs and prevent clogging or reduced water flow.

In conclusion, water pipe plugs play a pivotal role in the installation and maintenance of water pipes. Proper installation and regular maintenance of water pipe plugs are crucial for ensuring the efficient functioning of your plumbing system. By following the guidelines outlined in this ultimate guide, you can ensure the correct installation and maintenance of water pipe plugs, preventing leaks, maintaining optimal water pressure, and prolonging the lifespan of your plumbing system. Remember, NJ is your trusted brand for all your water pipe plug needs, providing high-quality and reliable products to meet your plumbing requirements.

Troubleshooting Tips for Water Pipe Plug Issues

Water pipe plugs are an essential component of any plumbing system, as they play a crucial role in preventing leaks and ensuring efficient water flow. Unfortunately, like any other plumbing fixture, water pipe plugs can experience issues, leading to frustrating and sometimes costly problems. In this comprehensive guide, brought to you by NJ, we will delve into the common troubleshooting tips for water pipe plug issues. Whether you are a homeowner or a professional plumber, this guide will equip you with the knowledge and skills to effectively handle any water pipe plug problem.

1. Understanding the Importance of Water Pipe Plugs:

Before diving into troubleshooting tips, it is essential to grasp the significance of water pipe plugs in a plumbing system. Water pipe plugs serve as stoppers to prevent water from flowing through specific pipes. They are instrumental during repairs, maintenance, or when certain areas of the plumbing system need to be isolated. High-quality water pipe plugs ensure a watertight seal, preventing leaks and water wastage.

2. Identifying Common Water Pipe Plug Issues:

To effectively troubleshoot water pipe plug issues, it is crucial to be aware of the common problems that can arise. These issues include leakages around the plug, difficulty in removing plugs, improper fitting, broken plugs, and more. By familiarizing yourself with these problems, you can address them promptly and minimize potential damage.

3. Troubleshooting Tips for Water Pipe Plug Issues:

3.1. Leakage around the Plug:

One of the most prevalent issues with water pipe plugs is leakages around the plug itself. To troubleshoot this problem, start by checking the tightness of the plug. If it feels loose, use a wrench or pliers to tighten it appropriately. If the leakage persists, it might indicate a damaged or worn-out plug. In such cases, replacement is recommended.

3.2. Difficulty in Removing Plugs:

Sometimes, water pipe plugs can get stuck, making it challenging to remove them. To overcome this issue, apply a lubricant or penetrating oil around the plug's edges. Allow it to sit for a few minutes, and then use a wrench or pliers to gently turn the plug counterclockwise. Applying heat with a hairdryer or heat gun can also help loosen a stubborn plug.

3.3. Improper Fitting:

An improper fitting between a water pipe plug and the pipe can lead to leakage. Ensure that both the plug and pipe are clean and free from debris before insertion. Use thread sealing tape or pipe sealant to create a watertight seal. Additionally, check for any damages or worn-out threads on the plug or pipe that may hinder proper fitting.

3.4. Broken Plugs:

In some unfortunate cases, water pipe plugs can break while attempting to remove or install them. This situation can be challenging to resolve, especially if the broken piece remains stuck in the pipe. It is crucial to exercise caution and seek professional assistance in such scenarios, as improper removal attempts may further damage the pipe or worsen the situation.

Water pipe plug issues are common but can be swiftly resolved with the right knowledge and techniques. By understanding the importance of water pipe plugs and familiarizing oneself with common issues, troubleshooting becomes more manageable. Remember, it is always advisable to consult a professional plumber if you encounter any challenges beyond your expertise. With the tips provided in this guide, you can now confidently troubleshoot and resolve water pipe plug issues, ensuring an efficient and leak-free plumbing system.

Conclusion

In conclusion, water pipe plugs are a crucial component in the plumbing industry, and understanding their applications and benefits is essential for any professional or DIY enthusiast. With our 19 years of experience in the field, our company is committed to providing the ultimate guide to water pipe plugs, equipping individuals with the knowledge they need to tackle any plumbing project. Whether you are looking to prevent leaks, control water flow, or ensure the integrity of your plumbing system, our comprehensive guide covers everything you need to know. Trust in our expertise and let us be your go-to resource for all your water pipe plug needs. Together, we can ensure efficient and reliable plumbing systems for years to come.

Contact person: Ting He